Mohala oa tlhahiso ea lijana tsa lijo

Mekhahlelo ea mantlha

| Ntho | Yuniti | Paramethara | Ela hloko |

| Mohlala | FS-FPP75-90 | ||

| Lisebelisoa tse sebetsang | GPPS granule | ||

| Botenya ba sehlahisoa | mm | 1-4 | |

| Bophara ba lakane | mm | 540–1100 | |

| Sekhahla sa ho foamisa | 12-20 | ||

| Boima ba bongata ba sehlahisoa | Kg/m³ | 50-83 | |

| Thermal conductivity ea sehlahisoa | W/mk | 0.021-0.038 | |

| Sephetho | kg/h | 70-90 | |

| Matla a lekantsoeng | Kw | 140 | |

| Phepelo ea motlakase | mekhahlelo e meraro 380v/50Hz | ||

| Boemo ba kantle | mm | 24000×6000×2800 | |

| Boima ba mochini o felletseng | Ton | Hoo e ka bang 10 |

Ⅰ 75/90 PS foam sheet extrusion line e kenyelletsa likarolo tse latelang

1. Mokhoa o itekanetseng oa ho fepa

1. Mokhoa oa ho fepa

Ho fepa ka moya

2. Mekhahlelo e ka sehloohong

| Bokhoni ba hopper ea mixer (kg) | 300 |

|

| Matla a Motlakase (kw) | 3 | |

| Matla a ho fepa a fepa (kg/h) | 200 | |

| Matla a motlakase a phepelo (kw) | 1.5 |

2 Mokhahlelo oa pele oa extruder

1. Screw and barrel material

Phekolo ea nitrogen ea 38CrMoAlA

2. Mokhoa o ka sehloohong oa koloi

Li-motor tsa AC tse nang le li-converter tsa maqhubu

⑶ Se fokotsa lebelo

Extruder e inehetseng e fokotsang, bokaholimo ba leino le thata, torque e phahameng, le lerata le tlase

⑷ heater

Aluminium casted heater, solid-state relay relay e se nang mabitso, mocheso o bohlale oa taolo ea mocheso

⑸ Litekanyetso tsa tekheniki

| Matla a ho khanna (kw) | 37 |  |

| Diameter ea screw bolt (mm) | Φ70 | |

| L/D karo-karolelano ea screw bolt | 32:1 | |

| Max rev of screw (rpm) | 60 | |

| Palo ea libaka tsa ho futhumatsa | 7 | |

| Matla a ho futhumatsa (kw) | 28 |

4 Mochini o sa emeng oa hydraulic othomathike oa ho nkela sebaka

Non-stop hydraulic sesebelisoa se fetolang kapele

Mekhahlelo ea mantlha

| Matla a pompo ea oli (kw) | 4 |   |

| Khatello e phahameng ea pompo ea oli (Mpa) | 20 | |

| Filter Net quantity (sekotoana) | 4 | |

| Matla a ho futhumatsa (kw) |

5 Mokhahlelo oa bobeli oa extruder

1. Screw and barrel material

Phekolo ea nitrogen ea 38CrMoAlA

2. Mokhoa o ka sehloohong oa koloi

AC-motor e nang le li-converter tsa maqhubu

⑶ Se fokotsa lebelo

Extruder e inehetseng e fokotsang, bokaholimo ba leino le thata, torque e phahameng, le lerata le tlase

⑷ heater

Aluminium casted heater, solid-state relay relay e se nang mabitso, mocheso o bohlale oa taolo ea mocheso

⑸ Mohatsela le mokhoa oa ho fokotsa mocheso

Pholiso ea metsi e potolohang, sistimi e iketsang ea bypass.

⑹ Litekanyetso tsa tekheniki

| Matla a ho khanna (kw) | 45 |  |

| Diameter ea screw bolt (mm) | Φ90 | |

| L/D karo-karolelano ea screw bolt | 34:1 | |

| Max rev of screw (rpm) | 30 | |

| Palo ea libaka tsa ho futhumatsa | 8 | |

| Matla a ho futhumatsa (kw) | 40 |

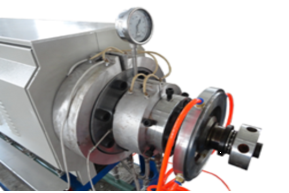

6 Hlooho ea Extruder le hlobo

1. Sebopeho

Potoloho ea hlooho ea extruder, molomo oa hlobo o khona ho ikamahanya le maemo, hlooho e nang le tekanyo ea khatello le sesebelisoa sa alamo ea khatello.Mofuthu oa hlooho o nang le pholileng ea metsi .

2. Boitsebiso

Boima: Ra0.025μm

Ts'epe ea boleng bo holimo, e phekotsoeng ke mocheso, bobolu ba kanale ea phallo: Ra0.025μm

⑶ Lintlha tsa mantlha tsa tekheniki

| Diameter of orifice hlobo | ho ea ka konteraka ea taelo |  |

| Bongata ba libaka tsa taolo ea mocheso | 2 | |

| Ho nepahala ha taolo ea mocheso (℃) | ±1 | |

| Matla a ho futhumatsa (kw) | 5 |

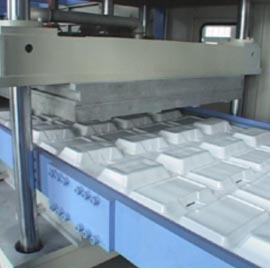

7 Sistimi ea ho futhumatsa le ho itšeha ea Shaping

1. Setaele sa ho bopa: moqomo oa ho bopa

2. Setaele sa ho pholile: moqomo oa sebopeho o pholile ka metsi le selikalikoe sa moea sa kantle

⑶Sebopeho: moqomo oa sebopeho, thipa e sehang le likarolo tsa rack

⑷ Mekhahlelo ea mantlha ea tekheniki

| Ho bopa boholo ba moqomo (mm) | Ho ea ka konteraka ea taelo |  |

| Matla a ho foka (kw) | Mantsoe a mararo 0.55 |

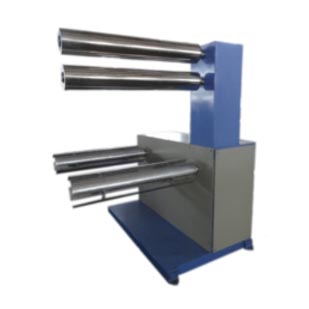

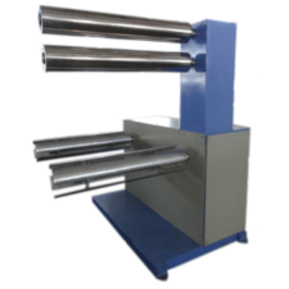

8 Sistimi ea ho hula

1. Setaele sa ho hula: li-roller tse 'nè tse bapileng

2. Foromo ea koloi ea ho khanna: AC-motor, modulation ea lebelo la ho fetola lebelo, se fokotsa lebelo se fetola lebelo

⑶ Lintlha tse ka sehloohong

| Ho hula palo ea rolara (sekotoana) | 4 |  |

| Ho hula boholo ba rolara (mm) | Φ260×1300 | |

| Matla a motlakase (kw) | 1.5 |

9 Sistimi ea ho felisa motlakase

| Adopt tod mofuta oa ion rod electrostatic felisa system, volt e sebetsang ke 7KV ka holimo, e ka hlahisa moea o phahameng o sebetsang le o matla oa ion, ka katleho ho felisa kotsi ea electrostatic. |  |

10 Sistimi ea moea

1. Sebopeho

Mofuta oa shaft ea matsoho a mabeli

2. Mekhahlelo ea mantlha ea tekheniki

| Boima ba ho kopanya (kg) | Boholo40 |  |

| Bophara ba khoele (mm) | Boholo ba 1100 | |

| Taolo ea bolelele | Taolo ea li-counter counter, fetola bolelele | |

| Mokhanni oa ho khanna | Torque motor 8n.m×4sets |

11 Sistimi ea taolo ea motlakase

| extruder futhumatsang laola cabinet | Sehlopha se le seng |   |

| Ea bobeli mohato extruder futhumatsang laola cabinet | Sehlopha se le seng | |

| matsoelintsoeke taolo khabinete | Sehlopha se le seng |

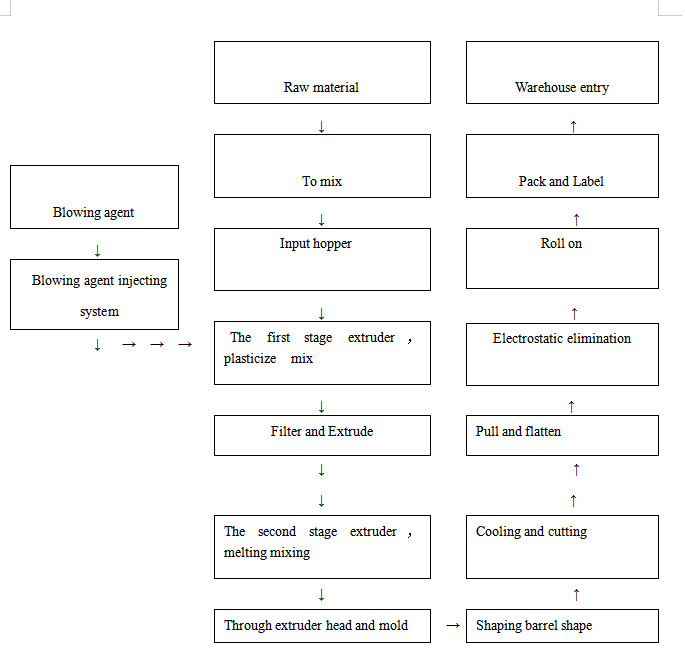

Ⅲ Chate ea phallo ea tlhahiso

Ⅳ Lintlha tsa mohala oa foam sheet extrusion

A. Mokhoa o itekanetseng oa ho fepa

1. Mokhoa oa ho fepa

Ho fepa ka moya

2. Mekhahlelo e ka sehloohong

| Bokhoni ba hopper ea mixer (kg) | 300 |

| Matla a Motlakase (kw) | 3 |

| Matla a ho fepa a fepa (kg/h) | 200 |

| Matla a motlakase a phepelo (kw) | 1.5 |

B. Mokhahlelo oa pele oa extruder

1. Screw le barrel thepa

Phekolo ea nitrogen ea 38CrMoAlA

2. Mokhoa o ka sehloohong oa koloi

Li-motor tsa AC tse nang le li-converter tsa maqhubu

3. Ho fokotsa lebelo

Extruder e inehetseng e fokotsang, bokaholimo ba leino le thata, torque e phahameng, le lerata le tlase

4. heater

Aluminium casted heater, solid-state relay relay e se nang mabitso, mocheso o bohlale oa taolo ea mocheso

5. Litekanyetso tsa tekheniki

| Matla a ho khanna (kw) | 37 |

| Diameter ea screw bolt (mm) | Φ70 |

| L/D karo-karolelano ea screw bolt | 32:1 |

| Max rev of screw (rpm) | 50 |

| Palo ea libaka tsa ho futhumatsa | 7 |

| Matla a ho futhumatsa (kw) | 28 |

C. Sistimi ea ho enta ea seqhutsu

1. Mofuta oa pompo

Mofuta oa plunger o nepahetseng haholo le pompo ea ho lekanya khatello e phahameng, ho bapisa valve ea tsela e le 'ngoe ho laola, molumo oa ente o laoloa ke ho phahamisa plunger.

2. Mekhahlelo ea mantlha ea tekheniki

| Mofuta oa ntho e fokang | butane kapa LPG |

| Phallo ea pompo ea metering | 40 (L) |

| Ente khatello e phahameng | 30 (Mpa) |

| Tekanyo ea khatello | 0-40 (Mpa) |

| Matla a motlakase | 3 (kw) |

D. Non-stop mochini haeteroliki jarolla ka ho iketsa filtara tsamaiso

Hydraulic e fetola sesebelisoa kapele

Mekhahlelo ea mantlha

| Matla a pompo ea oli | 4 (kw) |

| Khatello e phahameng ea pompo ea oli | 20 (Mpa) |

| Sefa palo ea nete | 4 (sekotoana) |

| Matla a futhumatsang | 8 (kw) |

E. Ea bobeli mokhahlelo extruder

1. Screw and barrel material

Phekolo ea nitrogen ea 38CrMoAlA

2. Mokhoa o ka sehloohong oa koloi

AC-motor e nang le li-converter tsa maqhubu

3. Ho fokotsa lebelo

Extruder e inehetseng e fokotsang, bokaholimo ba leino le thata, torque e phahameng, le lerata le tlase

4. heater

Aluminium cast heater, solid-state relay e sa amaneng le tlhahiso, mocheso o bohlale oa taolo ea mocheso, Sesebelisoa sa metsi a pholileng ka hitara.

5. Mohatsela le mokhoa oa ho fokotsa mocheso

Pholiso ea metsi e potolohang, sistimi e iketsang ea bypass.

6. Litekanyetso tsa tekheniki

| Matla a ho khanna (kw) | 45 |

| Diameter ea screw bolt (mm) | Φ120 |

| L/D karo-karolelano ea screw bolt | 34:1 |

| Max rev of screw (rpm) | 50 |

| Palo ea libaka tsa ho futhumatsa | 8 |

| Matla a ho futhumatsa (kw) | 40 |

F. Hlooho le hlobo

1. Sebopeho

Potoloho ea hlooho ea extruder, molomo oa hlobo o khona ho ikamahanya le maemo, hlooho e nang le tekanyo ea khatello le sesebelisoa sa alamo ea khatello.Mofuthu oa hlooho o nang le pholileng ea metsi .

2. Boitsebiso Ra0.025μm:

Ts'epe ea boleng bo holimo, e phekotsoeng ke mocheso, bobolu ba kanale ea phallo: Ra0.025μm

3. Lintlha tse ka sehloohong tsa tekheniki

| Diameter of orifice hlobo | Ho ea ka konteraka ea taelo |

| Bongata ba libaka tsa taolo ea mocheso | 1 |

| Ho nepahala ha taolo ea mocheso | ±1 (℃) |

| Matla a futhumatsang | 5 (kw) |

G. Ho bōpa tsamaiso ea ho pholisa le ho itšeha

1. Setaele sa ho bopa: moqomo oa ho bopa

2. Setaele sa ho pholile: moqomo oa sebopeho o pholile ka metsi le selikalikoe sa moea sa kantle

3.Sebopeho: moqomo oa sebopeho, thipa e sehang le likarolo tsa rack

4. Mekhahlelo ea mantlha ea tekheniki

| Ho bopa boholo ba moqomo (mm) | Ho ea ka konteraka ea taelo |

| Matla a ho foka (kw) | Mantsoe a mararo0.55 |

H. Ho hula tsamaiso

1.Setaele sa ho hula: li-roller tse 'nè tse bapileng, li hatella ka drive ea moea

2. Foromo ea enjene ea ho khanna: AC-motor, modulation ea lebelo la ho sokoloha ha lebelo, se fokotsa lebelo se fetola lebelo

3. Mekhahlelo e ka sehloohong

| Ho hula palo ea rolara (sekotoana) | 4 |

| Ho hula boholo ba rolara (mm) | Φ260×1300 |

| Matla a motlakase (kw) | 1.5 |

I. Mokhoa oa ho felisa motlakase

Adopt tod mofuta oa ion rod electrostatic felisa system, volt e sebetsang ke 7KV ka holimo, e ka hlahisa moea o phahameng o sebetsang le o matla oa ion, ka katleho ho felisa kotsi ea electrostatic.

J. Tsamaiso ea moea

1.Foromo

Mofuta oa shaft ea matsoho a mabeli

2. Mekhahlelo ea mantlha ea tekheniki

| Boima ba ho kopanya (kg) | Boholo40 |

| Bophara ba khoele (mm) | Boholo ba 1100 |

| Taolo ea bolelele | Taolo ea li-counter counter, fetola bolelele |

| Mokhanni oa ho khanna | Torque motor 8n.m×2 lihlopha |

K. Mokhoa oa ho laola motlakase

Khabinete ea taolo ea mocheso ea sethala sa pele sa extruder: sete e le 'ngoe

Khabinete ea taolo ea mocheso ea sethala sa bobeli sa extruder: sete e le 'ngoe

Khabinete ea taolo ea maqhubu: sete e le 'ngoe